OUR PROCESS

We make perfectly unrefined, stone ground chocolate from bean to bar at our Somerville, MA chocolate factory. Our unique chocolate-making techniques are all about minimal processing, to let the bold flavors of our organic, Direct Trade Certified cacao shout loud and proud.

1 - ROAST

Our vintage Barth Sirocco ball roaster lightly roasts our organic cocoa beans to highlight their naturally bright flavor.

2 - Winnow

Winnowing removes the tough outer shells from roasted cocoa beans, leaving us with intensely chocolatey cacao nibs – the main ingredient in our chocolate.

3 - Grind

Our stone mills use hand-carved granite millstones to lightly grind our cacao nibs into chocolate “liquor”: 100% dark chocolate!

4 - Mix

In our mixing tank, we blend the chocolate liquor with pure organic cane sugar grown sustainably by the Green Cane Project.

5 - Second Grind or Roll Refine

If we’re making our rustic Chocolate Discs, the next step is a second gentle grind in the stone mills, to preserve their signature gritty texture. If the batch will be bars, the chocolate runs through our roll refiner to make it slightly smoother.

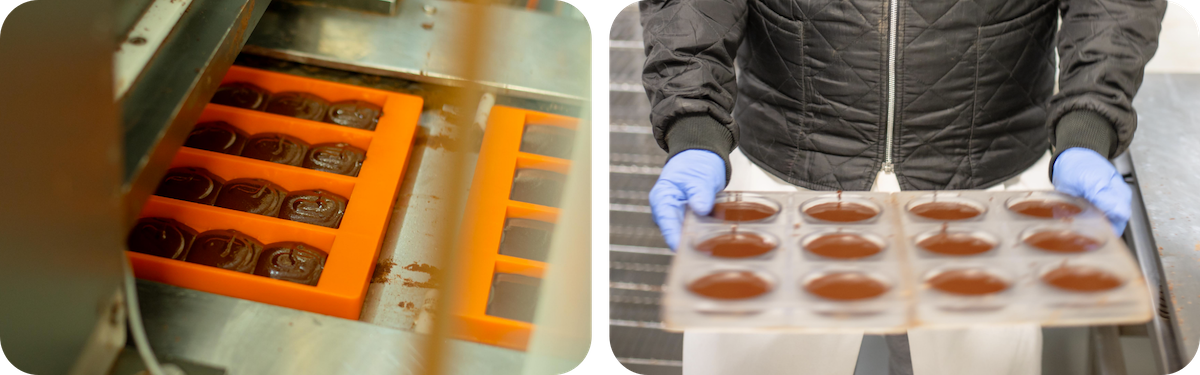

6 - Temper & Deposit

Tempering raises and lowers the temperature of chocolate in a precise sequence to ensure that the chocolate has a beautiful shine and snappy texture. The tempered chocolate is then deposited into molds.

7 - Chill & De-Mold

The molded chocolate chills out in our temperature controlled “cold room” until it’s just the right consistency to tap out of the molds.

8 - Package

Time to wrap it up! Our Wrap King machine can wrap 55 chocolate discs per minute, while our Loesch bar wrapper can package a speedy 70 bars per minute. Next stop: your favorite stores or direct to your home!

MADE BETTER

We only make chocolate from 100% organic, Direct Trade Certified cacao. Taza means better ingredients, better prices to farmers, and better chocolate for you.