2017 Transparency Report

TAZA CHOCOLATE DIRECT TRADE CERTIFIED CACAO

|

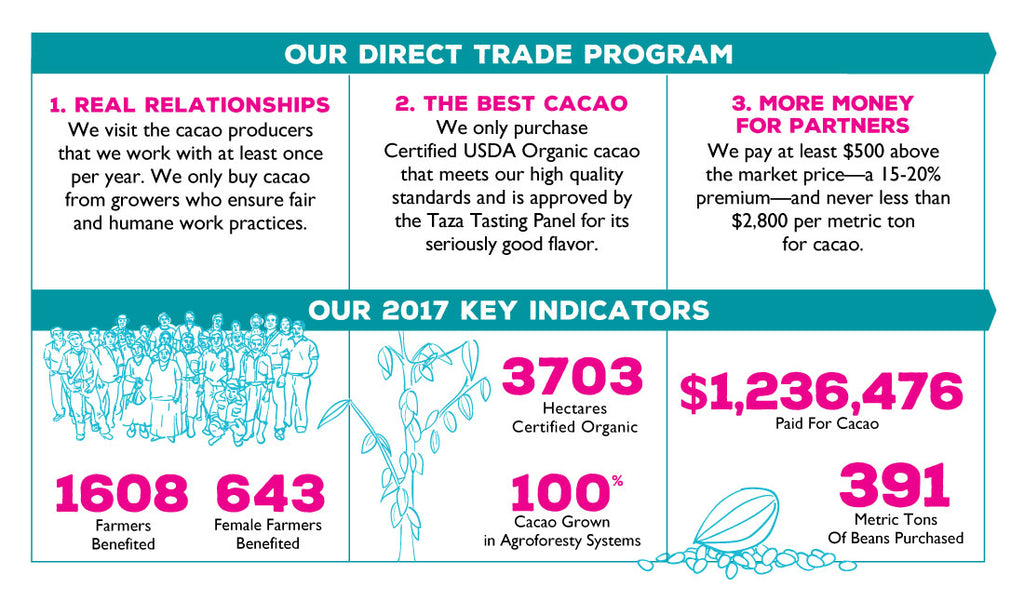

We are chocolate pioneers. Taza makes stone ground chocolate that is seriously good and fair for all. From farm to factory, we do things differently. We do things transparently. It starts with Taza Direct Trade. We said no to predatory middlemen and abusive labor practices. We created the chocolate industry's first third-party certified Direct Trade cacao sourcing program, to ensure quality and transparency for all. We have real, face-to-face relationships with partners who respect the environment and fair labor practices. They provide us with the best organic cacao, and we pay them prices significantly higher than Fair Trade. In fact, you can see exactly what we pay them, right here in our 2017 Annual Cacao Sourcing Transparency Report. Taza Direct Trade means more money for our partners, the best cacao for us, and seriously good chocolate for you.

THIRD PARTY CERTIFICATIONWe’re serious about transparency and trust. To guarantee the integrity of our Direct Trade program, our five Direct Trade claims are independently verified each year by Quality Certification Services, a USDA-accredited organic certifier based in Gainesville, Florida. See our five verified claims here. |

YEAR IN REVIEW: Origin Partners In Their Own Words

By Jesse Last, Taza Chocolate Director of Cocoa Sourcing | December 2017

Friends, PISA’s cacao processing plant sits in Haiti’s northern countryside surrounded by wild grasses and the occasional cow. The office is a small, white building, the first floor consisting of a desk, computer, printer, and a few well-worn books on cacao quality. The second floor became a bedroom at the start of the harvest when Aline, PISA’s Plant Supervisor, pulled a mattress up the stairs. But what the space lacks in comforts, it makes up for in convenience: Aline lives steps from where the cacao fermentation and drying happens. So at midnight, when the trucks return from the countryside weighed down with freshly harvested cacao, Aline oversees unloading. When at dawn, the beans need more oxygen to ferment, Aline coordinates their rotation through wooden boxes. Her 24-hour presence means fewer errors, higher productivity, and a team of workers motivated by Aline’s commitment to processing exceptional cacao. In last year’s Transparency Report, we explored the topic of price - how much Taza pays our Origin Partners like PISA who process cacao, how much these Partners pay the farmers who grow it, and most importantly, how price fits into the larger value equation of the supply chain. We sought to shine a light on the hard work of the farmers who provide Taza with exceptional cacao, and by pioneering a radical level of transparency down to the farm level, spark a larger conversation between farmers, processors, chocolate makers and consumers around the creation of a chocolate industry that is seriously good and fair for all. This year, we seek to highlight the efforts of another often hidden set of actors in our supply chain - the men and women responsible for collecting, fermenting and drying cacao beans. In Haiti, Aline and Fenise with PISA; in the Dominican Republic, Adriano and Gualberto with ÖKO Caribe, Isidro with Hacienda Elvesia, and Ramón with Finca El Majagual; and in Ecuador, Patricio with AgroArriba San Gregorio. These individuals represent Taza’s Origin Partners, and each has a unique story and perspective. What they share in common - beyond a version of Aline’s experience sleeping at one’s cacao processing plant during the harvest season - is a tremendous commitment to transforming fresh cacao beans into well-fermented and dried ones that our Somerville factory makes into Taza’s bold, flavorful chocolate. In this year’s Transparency Report, I begin with an overview of three critical phases of cacao bean processing and flavor development: harvesting, fermenting, and drying. My descriptions provide an overview, not a prescription: cacao experts actively debate the pros and cons of different approaches to processing cacao, and we are always learning more! Then, in our Partner Reports, our Partners share the realities of cacao processing in their own words. My hope is to provide an honest and compelling look at how - and thanks to whom - the slimy seeds of Theobroma cacao become the most delicious ingredient in chocolate. At Taza, we feel tremendous gratitude toward our Origin Partners. After reading our Report, we believe you will as well. Yours in Transparency,

Jesse Last |

3 STEPS FOR MAKING SERIOUSLY GOOD CACAO:

1. HARVESTING ⌵

The cacao harvest varies by country and depends on the local crop's genetics, the region’s climate, and the season’s weather. Taza Chocolate’s Origin Partners in the Dominican Republic, for instance, are busiest harvesting between April and July, while farmers in Ghana experience the larger of their two annual harvests between September and March.

Regardless of where and when it occurs, the cacao harvest is a manually-intensive effort. Using a sharp machete or a blade attached to a wooden pole for added length, a farmer removes ripe pods that grow directly off the cacao tree’s trunk and branches. Because not all pods ripen at the same time, a farmer visits the same tree multiple times during the harvest, and because different genetic varieties display colors that range from green to yellow to orange and red, she relies heavily on experience in deciding when a pod is ready to harvest. Removing a pod too early results in smaller seeds (“cacao beans”) and less sugary pulp; harvesting it too late allows the cacao beans to rot or germinate. Proper timing is crucial to quality.

Once cut from the tree, the football-shaped pods are carried to a central collection point and heaped in a colorful pile. In many although not all cacao growing communities, male farmers are responsible for breaking the pods open within a machete, rock or other blunt object within 24 hours, while women remove the seeds found inside. The number of beans within a pod usually varies between 30 and 50, roughly the amount needed to make a Taza Chocolate Amaze Bar.

Like the seeds of many fruits, cacao beans are covered in a sticky, delicious pulp when removed from the pod. One of my favorite parts of visiting a cacao farm is sucking this pulp directly off the freshly-harvested beans. The taste is sweet and slightly tart with flavors ranging from bright raspberry to ripe banana. It is best not to bite into the seed itself at this point, however - in its unfermented state, the bean usually has an earthy and astringent taste. Developing a cacao’s unique flavor requires step 2 of the processing journey, fermentation.

2. FERMENTING ⌵

Despite growing interest in the benefits of fermented foods such as yogurt and kombucha, few know about the critical role of fermentation in chocolate making. Fermentation begins the moment that fruit-covered cacao beans are removed from their pod and the pulp’s natural sugars come into contact with airborne yeasts. Piling the beans into a bucket or box limits the sugars’ exposure to oxygen and begins anaerobic fermentation, and over the course of 24 to 48 hours, microorganisms break down the sucrose into simpler sugars, ethanol, and carbon dioxide.

After this initial period, the beans are stirred or rotated every 24 or 48 hours for an additional three to five days. This movement exposes the cacao to oxygen and helps fuel the process by which natural bacteria transform the ethanol into acetic acid. Temperatures can reach up to 120 degree Fahrenheit during aerobic fermentation, and the beans become a hot, sticky mass that gives off a sweet, ripe aroma. The heat and acids break down the cacao’s astringent compounds, and the beans turn from purple to brown. Initial bitterness is transformed into nut, fruit and floral flavor notes.

This general process encompasses multiple approaches to fermenting cacao. The majority of the world’s cacao beans, especially those grown in West Africa, are piled onto banana leaves. They are covered with additional banana leaves to retain heat and stirred every couple of days. This approach’s greatest appeal is its low cost and simplicity. A second, less common method used primarily in Latin America and the Caribbean involves putting the beans into wooden boxes. Carefully managed, these boxes, often arranged in three or four levels, facilitate a controlled rotation and consistent fermentation of the beans. It also requires more money, time and energy.

Chocolate makers employ both physical and sensory evaluations to assess cacao fermentation. A common physical evaluation involves cutting 100, 300, or more beans in half (fortunately, an instrument known informally as the “guillotine” assists with this otherwise burdensome process.) Beans with physical defects such as mold or insect damage are removed, and those showing grooves and browned coloration are considered well-fermented. This number is then calculated as a percentage of the initial lot.

While a useful measure, fermentation rate does not define quality. Cacao beans’ genetics and terroir lend themselves to different fermentations, and a chocolate maker’s personal preference and final product (e.g. milk chocolate truffles versus dark baking chocolate) interact to determine the “right” fermentation rate. This is why turning beans into chocolate for sensory evaluation is so critical. For instance, Taza likes cacao from our Dominican partners to be 85-90% well-fermented, a rate at which we find its fruity notes shine brightest. Meanwhile, we ask our Ecuadorian partner for 75% well-fermented beans - an 85% rate would diminish this cacao’s floral and nutty notes.

While a bean’s perfect fermentation may vary by palate, most chocolate makers agree that once they find their ideal rate, they want it to stay consistent over time. If the Dominican cacao we used in our Wicked Dark bar dropped from 85% to 65% well-fermented, everyone would taste the lower acidity and higher bitterness! Achieving a consistent fermentation despite changes in temperature, rainfall, and other environmental factors is a tremendous challenge for our Origin Partners. The final step in the processing journey - drying the cacao - is another.

3. DRYING ⌵

With fermentation mostly complete, the beans hold a moisture level of around 60%. The moisture means mold can develop quickly, ruining all the painstaking work performed so far. Therefore, our Origin Partners transfer the fermented cacao from its boxes (or sacks or heaps) to flat surfaces such as concrete patios or wooden racks for sun-drying. Expert cacao processors know, however, not to expose the beans to direct, midday sunlight too quickly. Otherwise, the acetic acid built up during fermentation will be baked into the cacao bean rather than allowed to slowly break down and dissipate.

In order to develop a more stable drying process, Taza’s Origin Partners use solar tunnels consisting of a flat surface - again, a concrete patio, wooden racks, or metal trays - covered with a plastic roof or sheet stretched in an arc above the cacao. While the precise design of a solar tunnel can vary, the basic appearance is that of a greenhouse with the critical distinction that the solar tunnel is not fully enclosed. In fact, good solar tunnels are built to facilitate strong air flow and circulation that speeds up drying and prevents mold from developing.

Solar tunnels also protect cacao beans from the tropic’s fast-moving rains and moist nights. However, if the weather is wet or cold for an extended period, even a solar dryer may not be enough. To guard against these times, many of Taza’s Origin Partners also have one or two mechanical dryers consisting of an oven that heats air with natural gas and blows it beneath perforated metal trays covered in beans. While most experts agree that solar rather than mechanical drying leads to higher quality cacao, both are preferable to moldy beans.

Just as each cacao processor develops its own fermentation “recipe,” each has its own preference for drying cacao. Some like to dry the cacao in a solar dryer for several days before finishing the process with full sun exposure. Others never want the beans exposed to direct sun. Regardless of approach, all of Taza’s Origin Partners protect the cacao from rain, diligently rake the thin layers of drying beans to ensure consistency, and complete the drying process within 5 to 7 days.

Once the moisture meter reads 6-7% - or an experienced worker squeezes a fistfull of cacao beans and determines the same based upon feel and sound - the cacao processing is complete! The beans are either hand or machine cleaned to remove rocks and twigs, packed into 150 lb bags, and loaded into a shipping container for export. The beans will spend several weeks aboard a cargo ship before arriving at Taza to be stone ground into delicious chocolate!

OUR PARTNERS